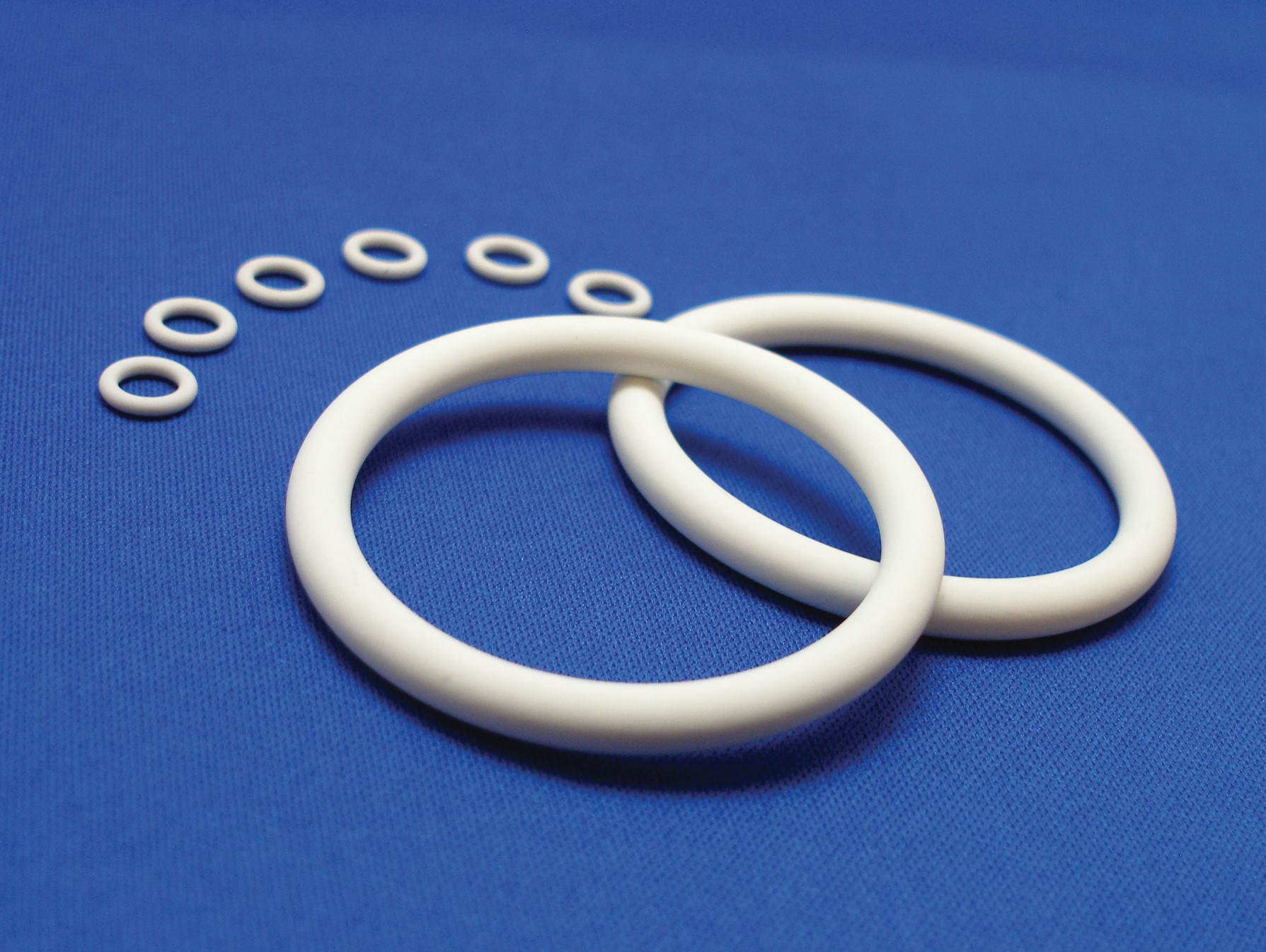

HyClamp™ Sanitary Gaskets

HyClamp™ sanitary gaskets – also known as Tri-clamp® and Tri-clover® seals – are designed to meet the needs of pipe couplings in food, beverage and pharmaceutical process lines.

Engineered to deliver optimal chemical resistance to satisfy the requirements of aseptic conditions, CIP (clean-in-place) and SIP (sterilization-in-place) processes, HyClamp™ seals provide excellent long-term sealing performance, while extending planned maintenance intervals and minimizing downtime.

Why use HyClamp™ hygienic gaskets?

Here are some of the key features and benefits of using HyClamp™ hygienic gaskets for pipe couplings in food and pharmaceutical process applications.

Sealing performance

Sealing performance

Material range

Material range

Fully compliant

Fully compliant

All sizes covered

All sizes covered

Exceptional service

Exceptional service

HyClamp™ sanitary gaskets are specifically developed to deliver exceptional long term reliable sealing performance in the most challenging conditions.

These gaskets maintain excellent sealing performance in temperatures between -60°C and 260°C, and offer virtually universal chemical resistance to all process media and sterilisation regimes.

HyClamp™ hygienic gaskets are available in materials to suit a broad range of industries and applications. Choose from FKM (fluoroelastomer), FFKM (perfluoroelastomer), silicone (VMQ), or EPDM, with metal-detectable material grades also available for peak contamination control.

HyClamp™ hygienic gaskets are compliant with major international food and pharmaceutical process standards, including FDA, USP Class VI, 3A 18-03 Sanitary Standards, and EC1935/EC2023. HyClamp™ materials are also free from animal-derived ingredients (ADI-free).

Parts are manufactured to BS4825, ISO2852 and DIN32676 standard sizes. PPE manufactures a range of hygienic connectors to fit various aseptic pipe couplings, including IDF gaskets, RJT O-rings, DIN11864 O-rings, DIN 11851 D-seals, and SMS seals. All HyClamp™ hygienic gaskets come with full manufacturing batch traceability, and are manufactured using tooling with non-wetted part lines to prevent bacterial build-up.

PPE provides fast and responsive lead times, with a full suite of seal design services supported by expert material and engineering development teams.

Sealing performance expand_more

Sealing performance expand_more

HyClamp™ sanitary gaskets are specifically developed to deliver exceptional long term reliable sealing performance in the most challenging conditions.

These gaskets maintain excellent sealing performance in temperatures between -60°C and 260°C, and offer virtually universal chemical resistance to all process media and sterilisation regimes.

Material range expand_more

Material range expand_more

HyClamp™ hygienic gaskets are available in materials to suit a broad range of industries and applications. Choose from FKM (fluoroelastomer), FFKM (perfluoroelastomer), silicone (VMQ), or EPDM, with metal-detectable material grades also available for peak contamination control.

Fully compliant expand_more

Fully compliant expand_more

HyClamp™ hygienic gaskets are compliant with major inte ational food and pharmaceutical process standards, including FDA, USP Class VI, 3A 18-03 Sanitary Standards, and EC1935/EC2023. HyClamp™ materials are also free from animal-derived ingredients (ADI-free).

All sizes covered expand_more

All sizes covered expand_more

Parts are manufactured to BS4825, ISO2852 and DIN32676 standard sizes. PPE manufactures a range of hygienic connectors to fit various aseptic pipe couplings, including IDF gaskets, RJT O-rings, DIN11864 O-rings, DIN 11851 D-seals, and SMS seals. All HyClamp™ hygienic gaskets come with full manufacturing batch traceability, and are manufactured using tooling with non-wetted part lines to prevent bacterial build-up.

Exceptional service expand_more

Exceptional service expand_more

PPE provides fast and responsive lead times, with a full suite of seal design services supported by expert material and engineering development teams.

HyClamp™ Gasket Range

BS4825-3 Gaskets expand_more

BS4825:1991 is the British Standard for stainless steel tubes and fitting for the food industry and other hygienic applications. Part 3 specification for clamp type couplings relates to the elastomer gaskets which are used to seal these couplings.

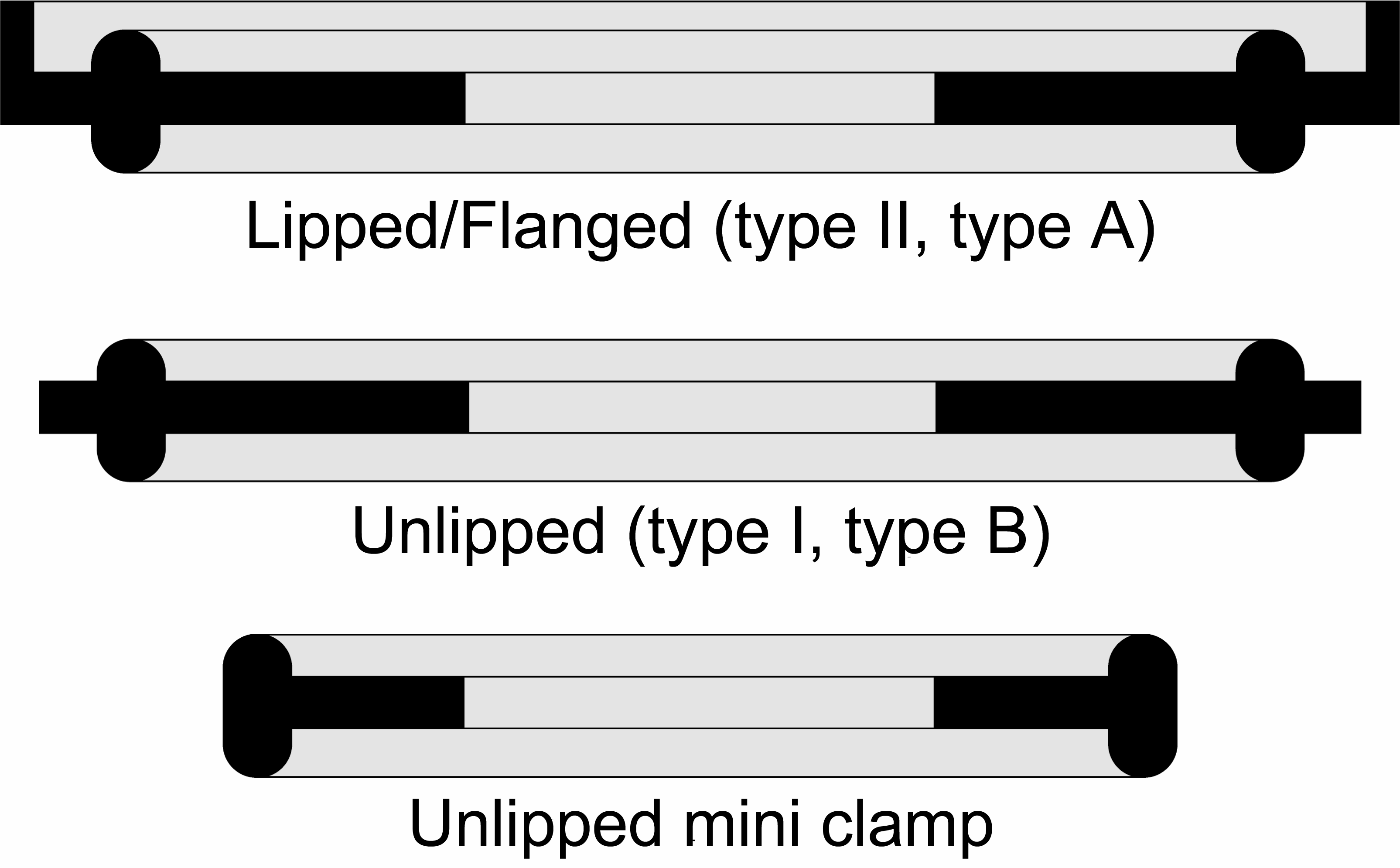

PPE manufactures HyClamp™ gaskets to BS4825-3 in various imperial sizes from 1″ to 4″ (nominal), including Type I (unlipped) and Type II (lipped) variations.

ISO2852 Gaskets expand_more

ISO2852:1993 is the Inte ational Standard for stainless steel clamp pipe couplings for the food industry.

PPE manufactures HyClamp™ gaskets to ISO2852 in various metric sizes from 12.00mm to 219.10mm (nominal), including Type A (lipped) and Type B (unlipped) variations

DIN32676 Gaskets expand_more

DIN32676 is the German Standard (Deutsche Norm) detailing fittings for the food, chemical and pharmaceutical industries and clamp connections for stainless steel tubes, including weld-on type.

There are three sections of the Standard which provide specifications for elastomer gaskets:

- Series A – metric sizes 10mm to 200mm (nominal) + mini clamp sizes 6mm to 8mm

- Series B – metric sizes 21.30mm to 219.10mm (nominal) + mini clamp sizes 10.2mm to 17.2mm

- Series C – imperial sizes 0.75″ to 6″ (nominal) + mini clamp sizes 0.25″ to 0.50″

ASME BPE Gaskets expand_more

ASME BPE is the inte ational standard for Bioprocessing Equipment published by the American Society of Mechanical Engineers. This standard gove s the design and construction of piping systems for hygienic service.

PPE manufactures HyClamp™ gaskets to ASME BPE in various imperial sizes from 1″ to 4″ (nominal), including lipped and unlipped variations, plus a range of mini clamp sizes.

Mini HyClamp™ Gaskets expand_more

PPE manufactures a range of compact HyClamp™ gaskets to DIN32676 and ASME BPE sizes. These hygienic gaskets are moulded in several elastomer material grades, including EPDM, silicone, FKM and FFKM.

Engineered to deliver optimal chemical resistance in pipe couplings for food, beverage, and pharmaceutical process lines.

Our high performance sealing materials:

HyClamp™ sanitary gaskets can be produced in the following material types:

Perlast®

expand_moreThe ultimate perfluoroelastomers for sealing applications where chemical resistance and high temperature performance are critical.

Detectaseal®

expand_moreMetal detectable and X-ray detectable elastomer compounds providing the latest in contamination detection and containment.

Available HyClamp™ materials

Perlast® G74S expand_more

Material Type: FFKM

Color: White

Temp Range (°C): -15 to +260

FDA: A-F

USP: 87+88

3A 18-03: Class I

Metal Detectable?: No

V70SW expand_more

Material Type: FKM

Color: White

Temp Range (°C): -15 to +200

FDA: A-F

USP: 87+88

3A 18-03: Class I

Metal Detectable?: No

Detectaseal® XE7A expand_more

Material Type: EPDM

Color: Blue

Temp Range (°C): -40 to +150

FDA: A-F

USP: —

3A 18-03: —

Metal Detectable?: Yes

Detectaseal® XS7H expand_more

Material Type: Silicone (VMQ)

Color: Black

Temp Range (°C): -60 to +200

FDA: A-F

USP: 88

3A 18-03: —

Metal Detectable?: Yes

View our range of high performance materials

Find your nearest sales contact

Resources

Below are some of our most popular resources for for HyClamp™ sanitary gaskets. For further information on this or any sealing topic, check out the Resources section.

This site is protected by reCAPTCHA and the Google Privacy Policy and Google Terms of Service apply.